Applicable Industries

1. Home appliance industry: printing of panels for rice cookers, induction cookers, washing machines, air conditioners, etc.;

2. Electronic industry: electrical membrane switch, flexible circuit board, copper foil, aluminum foil, LED circuit board;

3. Communication and information industry: mobile phone shells, mobile phone buttons, battery accessories, computers and peripheral terminal equipment, etc.;

4. Clothing and textile industry: transfer printing and non-inductive labels in clothing and textile;

5. Traffic signs: containers, car compartment labels, motorcycle/bicycle decals, etc.;

6. Instrument industry: electronic switches, instrument panel labels;

Advantages

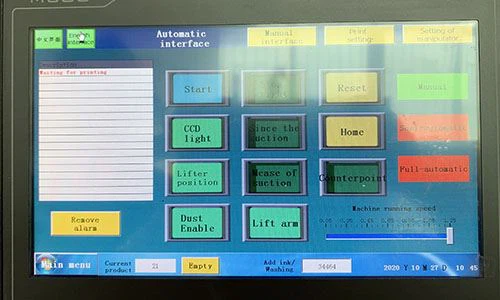

1. The touch screen man-machine interface control is fully automated and easy to operate

2. Multi-color printing automatic CCD visual alignment, accurate and stable color registration, and the accuracy can reach 0.02mm

3. Using servo motor, printing, ink return, speed, distance and quantity can be set at will

4. The three-stage suction device can adjust the strong and weak wind according to the requirements of the printing material

5. Equipped with an off-screen function to prevent the screen from sticking when printing a large area of background color and printing glue

6. Equipped with a dust removal roller, which can remove dust on the bottom surface of the material surface

7. Photoelectric control of feeding and receiving to avoid scratches on the surface of the substrate

8. Set the number of printing and automatic shutdown and alarm if there is no material; automatic shutdown and alarm if abnormalities are found

9. Cool hanging ring drying, automatic constant temperature and automatic material collection according to the requirements of printing materials, uniform heating, no deformation

10. Optional air-conditioning device, re-release paper function, automatic waste discharge, protective film collection device.

Product Parameters

| Model | VT5070PR-1 |

| Workingplace area(mm) | 1000x660mm |

| Max inputting width | 450mm |

Max printing area | 600x450mm |

| Min printing area | 400x500mm |

| printing thickness | 0.075-0.5mm |

| CCD alignment precision | ±0.02mm |

| Printing precision | ±0.05mm |

| Air pressure | 4 - 6 kg/PSI |

| Air consumption | 2.6L/cycle |

| Voltage | 380V-50HZ |

| Power | 5KW |

| Max size of screen frame | 1100x800mm |

| Min size of screen frame | 300x200mm |

| Mix print skip distance(mm) | 2 |

| One time printing speed(printing number/hour) | 1000-1200 |

Machine size | L3300mmxW1600mmxH2200mm |

| Machine weight | 1500kg |

Product Description

| Feeding Machine -----Unwinder ◆The starting speed of unwinding can be adjusted at will. ◆Adopt photoelectric control to discharge the material to avoid scratches on the surface of the material; ◆ Unwinding speed and time can be adjusted at will; ◆ Equipped with automatic tearing film function; ◆ Automatic shutdown without material; |

Corrector controller ◆Aviation plug connection, convinient and safety. ◆ Mass adopts aluminium alloy, effectively reduce the driving inertia, reduce response time. ◆ Special guide rail design makes moving parts highly tightly connected, combine with controllation, control to stably work under 4HZ response frequency and have no concussion. ◆ Max tension is 400~450N. |  |

| CCD Printing Table and Printing Head ◆ CCD window on the printing table for alignment, printing table will automatically rotate to position. ◆The scraper and squeegee can be adjusted separately, and the squeegee can be used on both sides to extend the service life; ◆Using numerical control motor, printing and ink return distance and speed can be set freely. ◆The tension of the machine adopts suction design to avoid material scratches and keep the tension constant. |

| Touch Screen Operation User-friendly PLC control combined with touch screen monitor for maximum operational convenience. The default language is Chinese-English, customer can convert to use, we also accept other language customization. The touch screen is used to control the lifting of the printing head to facilitate the maintenance, loading, unloading and cleaning for the screen and scraper; |  |

| CCD Registering System Printing is performed automatically via CCD positioning and the CCD field of view is adjustable as per material dimension. CCD automatically calculates the spatial positions of the material and the screen according to the Mark points on the material and then commands X, Y and θ of the motor motion control and adjusting platform to rotate for automatic positioning printing. |

| Quality Inspection Glass Table It is equipped quality inspection light to inspect printed material, it's convenient to find the Defective product |  |

Printed Samples

Company & Workshops

Packing & Shipping

CE Certificates

Our Service

1. Supporting on-site & online installation.

2. Professional and efficient training will be offered.

3. In case something happened, support quick trouble shooting.

4. Spare parts and consumable parts supply are available.

5. Life-long maintenance is supported.

Hot Tags: high precision ccd positioning screen printer, China, factory, customized, pricelist, quotation, low price, hot sale, machine for screen printing, 4 screen printing machine, automatic screen printing press, types of screen printing machine, high precision screen printing machinery, automatic screen printer for IMD IML